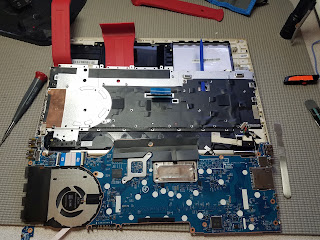

I installed the backlit keyboard in my HP laptop this weekend. What a

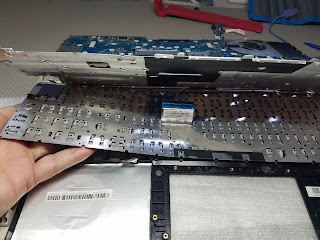

chore that was! I used my soldering iron to melt all the plastic

rivets, carefully prying up the metal back plate as I went along until I

could lift it enough to have access to the underside of the keyboard. I

then had to melt more rivets so that I could pry up the keyboard. When I

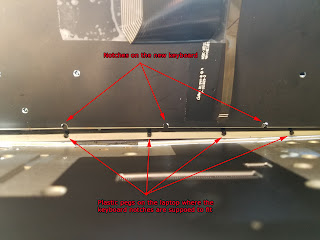

put the new backlit keyboard in I found that there were three notches

which did not line up with the plastic pegs on the laptop. Argh!

The backside of the keyboard is metal so I couldn't just use scissors

or a utility knife to cut out notches, and my tin snips don't offer the

level of precision I would need, so the only option I could see was to

cut off the plastic pegs that didn't align. There wasn't enough room to

get even a small utility knife in there so I cut them with nail clippers

and then filed them down the rest of the way with a metal nail file.

Once I put the new keyboard in place I made some new notches with hot

glue. I also used hot glue to recover all the plastic rivet tops I had

melted away. I had tried spreading the plastic out with the soldering

iron to make new heads but it just wasn't working.

I spent pretty much the entire day on this keyboard replacement and

am happy that I got it done and it worked. This keyboard feels much

nicer than the original and has a backlight so I can see what I'm doing

even in low light. The whole process soured me on HP, though. They could

have used screws or plastic clips but no, they designed it this way on

purpose. Not cool, HP! I'll definitely think twice about purchasing an

HP laptop in the future.

No comments:

Post a Comment